Positioned as the valve supplier for the

world’s leading automobile brands, and

as the largest engine valve manufacturer

in Turkey with the widest product range,

Supsan continued to move forward

in the 2020 operating period, which

coincided with its 50th anniversary. In a

year overshadowed by COVID-19, Supsan

continued production processes without

interruption due to measures taken to

safeguard the health of employees during

the pandemic. Despite the difficulties

faced in the period, Supsan maintained

its visionary strategies for the future

and invested in the serial production of

Turkey’s first sodium-filled Hollow engine

valves.

Strategic Positioning

Operating as a Borusan Holding

company, Supsan carries out distinctive

business processes thanks to the following

competitive advantages:

• Turkey’s largest manufacturer of engine

valves,

• The widest range of engine valves,

• Executor of the most advanced,

technological methods in engine valve

production,

• The first plant with serial sodium valve

production capability in Turkey, keeping

abreast of technology developments in

engine valves,

• Leader of the domestic Original Equipment

Manufacturer (OEM) and spare parts

market,

• Capability to reach more customers in

turbocharger production every year,

• A corporate strategy focused on meeting

the needs of the automotive spare parts

market,

• Efforts to become a sensitive parts

manufacturer in automotive sector,

• Project activities linked with process

digitalization and robotic practices under

Industry 4.0.,

• Capability to manufacture any type of

valve,

• The only brand that commenced

turbocharger production in addition to

valve-only production activities and the

brand with the widest product range in

automotive parts,

• An infrastructure that meets all the

expectations of OEM customers with IATF

16949, OHSAS 18001, ISO 14001, and Ford Q1

certificates,

• Solid know-how owing to its place among

the top 250 companies with the highest

R&D spending,

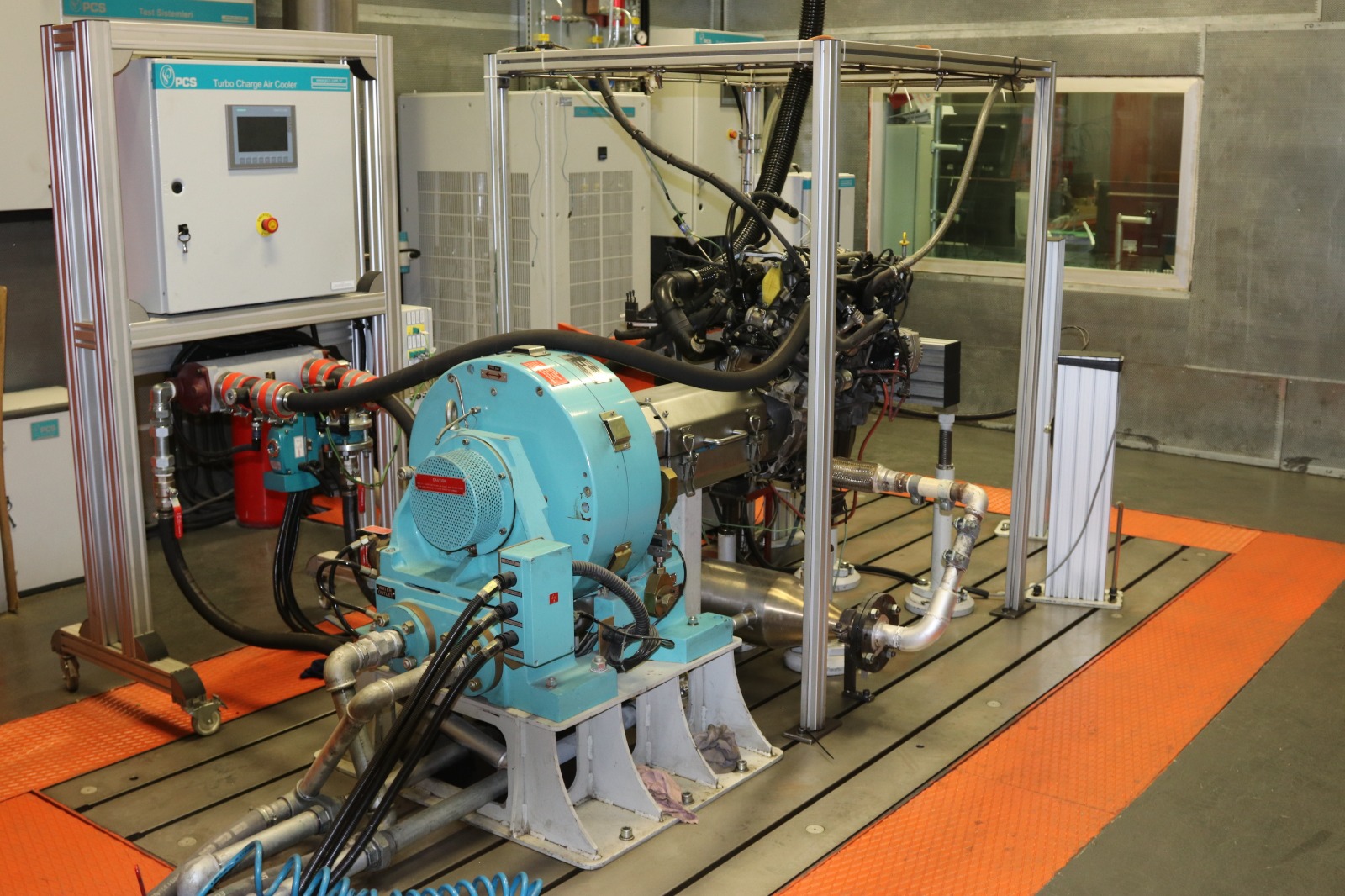

• Engine testing infrastructure.

Supsan Ranks among the Top 250

Companies with the Highest R&D Spending

Due to its R&D investments during the

year, Supsan ranked among the top 250

companies with the highest R&D spending

according to the survey “R&D 250:

Companies with the Highest R&D Spending

in Turkey.” The Company continued R&D

and digitalization investments despite the

COVID-19 pandemic and spent a total of TL 5

million for 13 R&D and digitalization projects

during the 2020 operating period. Of these 13

projects, six involved product development,

two involved process development, and five

involved Industry 4.0 and digitalization. Four

projects were finalized in 2020.

Supsan acquired a comprehensive Computer-Assisted Engineering (CAE) software infrastructure, which positioned the Company as an engineering service provider for OEM clients. Capabilities of the existing engine testing room were enhanced; as a result, Supsan became further equipped to undertake more comprehensive engine tests. Capabilities regarding testing processes under product development and R&D projects were also improved. Supsan automated numerous processes through the Robotic Process Automation (RPA) software included in digitalization efforts.

Supsan’s spending on 13 R&D and digitalization projects conducted in 2020 reached TL 5 million.

Processes driven by RPASupsan automated numerous processes via the Robotic Process Automation (RPA) software included in digitalization efforts.

An important project for Supsan is the “Hollow Valve Design and Production” project, a joint project with a leading OEM producer supported by TÜBİTAK (Scientific and Technological Research Council of Turkey). The design and prototype production under this project have been completed, and testing of these sodium filled hollow valves has started.

From Engine Valve Manufacturer to

Engineering Solution Partner

Supsan has utilized the most advanced

technologies since its founding. With its

engineering infrastructure established in

recent years, the Company now provides

support to OEM clients as an Engineering

Solution Partner in next-gen engine projects.

An important project for Supsan is the

“Hollow Valve Design and Production”

project, a joint project with a leading OEM

producer supported by TÜBİTAK (Scientific

and Technological Research Council

of Turkey). The design and prototype

production under this project have been

completed, and testing of these sodium-filled

hollow valves has started. Another project

supported by TÜBİTAK is underway through

CAE activities aimed at boosting energy

efficiency in heat treatment processes.

“Turbocharger Design Tool Development”

is another important project conducted

by Supsan. Under this project, a software

program was developed that enabled a

turbocharger design from scratch so as

to match the characteristics of the engine

owned by OEM clients. Relevant works were

performed as part of a Ph.D. dissertation.

Regarding Industry 4.0 activities, the “Data

Collection System Development” project

was carried out. As a result, a system was

installed that collects data and monitors the

status of the units within auxiliary facilities

that are critical to the functioning of the

plant. This system was aimed at proactively

diagnosing failures. In innovation activities,

the focus was on potential new products

and business models for Supsan. Evaluations

were made regarding new products, and

business models were either developed

internally or proposed by customers.

Firm Steps Towards Sustainability and

Digitalization

In an effort to move its corporate structure to the

future, Supsan continued to take successful steps

towards sustainability and digitalization in 2020.

• Supsan identified certain areas under the

United Nations Sustainable Development

Goals and adapted them to its strategy to

more effectively assess the progress achieved

towards sustainability and the results of this

progress.

• Systematic works are performed to reduce

waste and address the opportunities linked with

the circular economy. In this respect, economic

benefits were gained in 2020 by recovering

the metals inside the waste that form on the

central filters of cutting and cooling oil.

• Efforts towards reduced carbon emissions

continued; two R&D projects on energy

efficiency were completed, and one R&D

project continued.

• Upon the request of a leading domestic

OEM client, a Corporate Social Responsibility

assessment was completed on the Ecovadis

platform; as a result, the Company was

granted a “Gold Medal” for its sustainability

approach.

• In 2020, findings obtained from the annual

Employee Engagement Survey were above

the average rates in the sector both in Turkey

and around the world, again demonstrating

the Company’s success and the importance it

attaches to employees.

• Action plans have been formulated to

implement the “Green Plant” concept in new

enterprises, which places sustainability at the

heart of all activities related to new investment

projects.

Supsan took the following steps towards digital

transformation:

• Five Industry 4.0 and Digitalization projects

were carried out in 2020 to minimize potential

failures and errors in production and internal

processes, achieve time savings, and prevent

financial losses that might arise from such

failures/errors.

• In Industry 4.0 activities, a “Data Collection

System Development” project was carried

out. As a result, a system was installed that

collected data and monitored the status of the

units within auxiliary facilities that are critical to

the functioning of the plant.

• The incorporation of an RPA software program

was the highlight development of Supsan’s

digitalization drive. The software program

rapidly automates routine and time-consuming

processes that do not require human

intervention.

Action plans have been formulated to implement the “Green Plant” concept in new enterprises, which places sustainability at the heart of all activities related to new investment projects.

"Gold Medal"Upon the request of a leading domestic OEM client, a Corporate Social Responsibility assessment was completed on the "Ecovadis platform;" as a result, the Company was granted a “Gold Medal” for its sustainability approach.

Moving the corporate structure into the futureAdvancing its corporate structure to the future, Supsan continued to take successful steps towards sustainability and digitalization in 2020.

Measures Taken Against the COVID-19

Pandemic

Supsan executed several projects to mitigate

the impact of the COVID-19 pandemic and

guarantee the continuity of production.

• Facial masks and protective shields were

distributed to all employees.

• Employees’ temperatures are checked

before each shift, during the lunch break,

and prior to the use of shuttles.

• The capacity of shuttles was cut by 50%

in a manner to ensure social distancing

for each employee, and the seating was

logged in the shuttle seating plan on a

weekly basis.

• End times for each shift were adjusted to

ensure that only a designated number of

people use the changing room at a given

time.

• Changing rooms were regularly ventilated,

and all the areas and working sites within

the plant were disinfected weekly.

• White-collar employees shifted to the

partial remote work system.

• Employees who are included in a risk

group per the workplace doctor’s opinion

do not come to the physical working

space.

• Adjustments were made in break times to

limit the number of employees taking a

break.

• Coffee machines and water fountains were

turned off and water distributed to each

production line and office in closed bottles.

• Checks were performed throughout

the day to ensure that necessary

measures are taken if the healthcare unit professionals find a risk factor in

an employee and that the employee is

redirected to the contracted hospital for

testing.

• Mealtimes were re-adjusted. The number

of employees who can be present at the

cafeteria at the same time was halved. The

location of tables was altered to provide

the social distance required. Adjustments

were made to allow only two people to sit

at each table, and tables were divided into

two sections with separators. Tables used

by employees have been logged into the

seating schedule on a weekly basis.

• Foods and beverages in common

places, e.g. salads, water, spices, at the

cafeteria were removed and distributed to

employees in disposable packages.

• Markings were placed as reminders of

social distancing rules in the cafeteria,

changing rooms, infirmary, production

card scanning areas, and offices.

• Overseas and domestic travel was

postponed, and employees who returned

from trips quarantined for 14 days.

• Meetings, courses, or project presentations

are now held solely on online platforms.

• Decisions passed by the Ministry of Health

are monitored continuously, and the

Company complies with each decision

taken.

• Risk analyses and an emergency plan

have been prepared for the COVID-19

pandemic as per applicable laws. Drills

were conducted for emergencies;

shortcomings, as identified in these drills,

were remedied promptly.

A Pioneer of Corporate Social

Responsibility Projects

In 2020, Supsan undertook numerous

corporate social responsibility projects,

serving as a model for its stakeholders as an

exemplary corporate citizen. The Company

executed the following projects in the 2020

operating period:

• Protective shield support to healthcare

workers,

• TEGV Sponsorship at the Lego Robot

Tournament and the team being granted

the best presentation award,

• Adopting blind cats,

• Support for the Plastic Lid Collection

project of TOFD.

A Look into the Future

Supsan will continue operations in parallel

with its vision of becoming a preferred

destination in and outside Turkey for

the engineering, production, and supply

of precision machined parts for new

technologies. Other than engine valves,

the Company aims to identify customers’

requirements for precision machined parts

and undertake efforts to become a supplier

of these parts. In addition, Supsan has

targeted supplying turbocharger product,

which has been sold on the aftermarket

since 2014, for the Original Equipment

Manufacturers. It will continue its activities

geared towards this goal. Another aim is to

continue efforts to boost the market share of

aftermarket products.

Meetings, courses and project presentations are now held solely on online platforms.

Emergency planRisk analyses and an emergency plan have been prepared for the COVID-19 pandemic as per applicable laws.

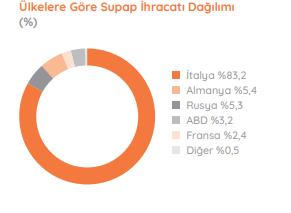

83%

Italy represented 83% of Supsan’s total exports in 2020.

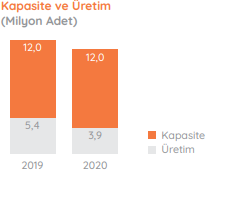

3.9 million engine valves producedSupsan produced 3.9 million engine valves throughout 2020.

ATINÇ OCAK

ATINÇ OCAKGeneral Manager

Supsan

COMPANY PROFILE

SupsanOperational Information

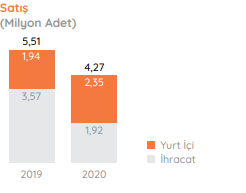

• Total Production: 3.9 million units

• Global Sales: 1.92 million units

• 2020 Valve Sales: 4.27 million

units

• Exports to Italy: 83%

Production Capacity

• 12 million valves a year

• 3 million stellated valves

• Capacity for 3.3 million

two-piece valves

Corporate Information

Field of Activity

• International expertise in the

manufacturing and aftersales

services of engine parts and other

related products in the original

equipment and aftermarket.

• Valve production for internal

combustion engines under the

license of Eaton SRL, the leading

manufacturer in the global market.

Sectors Served

• Domestic and international OEM

and after-market customers

Service Locations

• Headquarters: Halkalı Plant

• Independent Spare Parts: 100

dealers

Partnership

Eaton

Products and Services

• Domestic OEM

• Domestic OES

• International OEM & OES