Borçelik is the highest quality galvanized steel producer with the largest production capacity in Turkey.

Borçelik was founded in 1990 as the first private and the second largest flat steel producer in Turkey. The Company has started its business operations with producing cold-rolled steel in 1994. Borçelik has increased its production capacity to 1.5 million tons with the investments made in the years 1994, 2003 and 2008 which costs totally 530 million USD. Borçelik has three cold-rolling and three hot dip galvanized steel lines. As Turkey’s largest galvanized steel producer, Borçelik offers the highest quality products with 900 thousand tons of galvanized capacity.

Borçelik operates as a partnership of Borusan Holding and ArcelorMittal, one of the world’s leading integrated steel and mining companies.

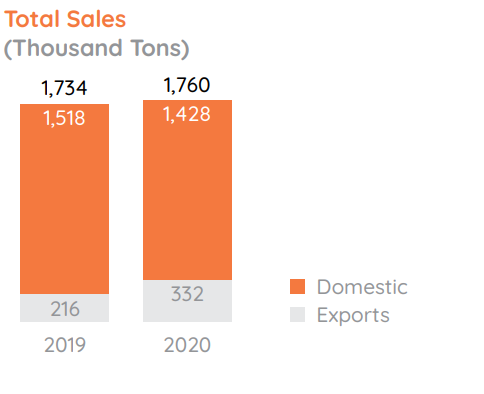

Borçelik has a total production capacity of 1.5 million tons under the Borçelik brand and a metal processing capacity of 500 thousand tons under the Kerim Çelik brand. As of year-end 2020, Borçelik recorded product sales totaling 1.8 million tons.

Strategic Positioning

In line with its vision, Borçelik aims to become the number one flat steel solutions provider for its key sectors in target territories by focusing on customer proximity, efficiency, and innovation. Borçelik’s competitive advantages include:

• With extensive experience and know-how, Borçelik is the first private flat steel producer in Turkey.

• Turkey’s market leader in the hot-dip galvanized steel industry

• Main supplier to leading industrial OEM’s of Turkey

• Kerim Çelik, Turkey’s first steel service center at global standards, with more than 50 years of experience.

• Merged rerolling and SSC operations to provide flexibility and higher market penetration

• Strategic partnership with ArcelorMittal, one of the world’s leading integrated steel and mining companies.

In 2020, Borçelik recorded product sales totaling 1.8 million tons.

Over 50 years of experienceKerim Çelik is Turkey’s first steel service center at global standards, with more than 50 years of experience.

.jpg)

Sustainable Financial and Operational Results

As of year-end 2020, Borçelik recorded sales totaling 1.8 million tons and exports of 332 thousand tons. Even though the year 2020 was a difficult year overshadowed by COVID 19, Borçelik followed new pandemic initiative " I protect my employees, my business, my stakeholders” and successfully achieved continuity in production.

Especially during the breakout of pandemic, where domestic demand was dropped abruptly, Borcelik followed closely export markets, where its competitive edge can be utilized and direct its volumes to those markets. In later stages of the pandemic, the domestic demand revived and Borcelik quickly shifted its production again to domestic OEM’s. The company’s agility and service flexibility in those difficult periods translated to positive business results and Borçelik continued to add value to its stakeholders in 2020.

In 2020, Borçelik accounted for 17% of Turkey's total cold-rolled and galvanized steel exports. Borçelik's priority is producing and supplying for domestic customers and the Turkish economy. However at the same time, Borçelik historically always kept a decent share for exports to balance its portfolio and to have an international presence.

As in previous years, Borçelik recorded a high-capacity utilization rate in 2020

R&D, innovation, and digitalization initiatives continued in 2020. Borçelik's internal focus was on health and safety, cost reduction, productivity and industry 4.0 incentives. Externally, Borçelik focused on new products and enhanced customer service.

In 2020, Borçelik accounted for 17% of Turkey’s total cold-rolled and galvanized steel exports.

Exports to 38 countries

Borçelik's priority is producing and supplying for domestic customers and the Turkish economy. However at the same time, Borçelik historically always kept a decent share for exports to balance its portfolio and to have an international presence.

As part of an R&D project carried out for Tofaş, Borçelik contributed to the production of rear inner door frames for Fiat Egea in 2020. Under this effort, 3 thousand tons of rear inner door frame were produced with Borçelik steel for Fiat Egea.

Investments in R&D and Innovation

In 2020, Borçelik moved forward on its R&D strategies and technology roadmap. During the year, Borçelik continued projects, which were designed to create added value in Process, Material, and Technology development. Some of these projects were completed this year. Borçelik is already benefiting from the actual results and contribution of certain projects. In 2020, Borçelik submitted eight applications to expand its EU funded project portfolio. Thanks to these efforts, Borçelik now has three projects actively funded by the EU. In the intellectual property rights arena, Borçelik has seven projects underway. Five congress/conference presentations were made during the year despite the pandemic. In 2020, Borçelik submitted a project application for TÜBİTAK’s Order-Based R&D Call for Papers. The project was accepted by TÜBİTAK with wide support. Partnerships with universities continued in the 2020 to provide technical assistance to projects and create new areas of learning. Joint project agreements were signed with three universities under the TÜBİTAK 2244 Industrial Doctorate Program.

In the area of material development, Borçelik conducted studies to domestically develop the steel qualities currently imported and not produced domestically by the automotive sector. During the year, industrial trial production processes for two important new qualities were completed and client approval processes commenced. Efforts are underway to add two new products to the current portfolio in 2021.

As part of an R&D project carried out for Tofaş, Borçelik contributed to the production of rear inner door frames for Fiat Egea in 2020. By using BORMECH – which contains mechanical testing data of coils and creates a coil-based material data card for shaping simulations – Borçelik focused on reducing mold set-up times and realizing rapid mass production of Fiat Egea with collaborative work. Under this effort, 3 thousand tons of rear inner door frame were produced with Borçelik steel for Fiat Egea.

Two process development projects that improve process efficiency and boost occupational safety were completed during the year. These efforts proved exemplary in terms of the transfer of R&D capabilities to the field. Borçelik also played a major role in projects related to coatings with high corrosion resistance and coatings with advanced surface qualities. These various efforts were focused on commercializing a product.

In 2020, Borçelik commercialized eight innovation projects. Sales tonnage and portfolio expansion efforts were conducted for these projects. In addition, five ideas were studied to develop a new funnel-oriented product with enhanced capabilities. One of the ideas was turned into a full R&D project in the 2020 operating year. Three of the ideas were included within the referenced project’s scope. The infrastructure for the one remaining idea was organized for sales.

Borçelik’s Digital Transformation Journey

• In 2020, the preliminary development and testing of the SpeedAP SAP Hana project, the backbone of the organization’s digital transformation, was completed successfully. This effort aims to achieve a more agile, up-to-date, and faster technology structure. The project was implemented on March 1, 2021.

• Launched in 2019, the Advanced Planning and Optimization project continued to move forward during the year. This initiative aims to integrate management of supply chain processes from demand planning to scheduling.

• The Digital Maintenance Platform, Forklift Operations Process Digital Transformation, and Trailer Operations Tracking projects, which support new technology applications at the Borçelik production site, were successfully implemented in 2020.

• All Borçelik business processes that will serve as the systems infrastructure of the digital transformation were reviewed. These processes were redesigned based on the end-to-end value structure from the original functional structure.

• In 2020, Borçelik successfully implemented the world's first Virtual Reality-based Overhead Crane Simulator with Cabin/Control.

• With the video analytics system designed with deep learning algorithms using existing camera systems, occupational health and safety measures are monitored in order to prevent work accidents.

In 2020, Borçelik commercialized eight innovation projects. Sales tonnage and portfolio expansion efforts were conducted for these projects.

Artificial intelligence algorithmsBorçelik focused on developing special sensors and AI algorithms for the flat steel sector under the Industrial Sensing for Smarter Europe (IS4SE) initiative.

Contribution to Social Development

Continuous Support from Borçelik Employees to Healthcare Workers and the General Society throughout the Pandemic!

During the pandemic, Borçelik employees volunteered for numerous campaigns in support of healthcare workers – who selflessly battle against COVID-19 – and society at large. Borçelik Maker Club (BMK) started to produce protective face shields with their 3D printer for hospitals in Bursa. Borçelik Volunteers distributed 3800 face shields to healthcare institutions in urgent need and met 15% of Bursa's total need for protective shields. In addition, BMK partnered with Uludağ University's Anesthesiology and Reanimation Unit in developing the Laryngoscope U-profile for use in pediatric and adult patients. For Yedikule Respiratory Diseases Hospital, BMK produced components that play a role in the functioning of saturation devices measuring blood oxygen and cardiac rhythm as well as in ECG devices, both used in COVID-19 cases. These critical components were also delivered to the required locations.

Under the Borçelik Fund for Contribution to Education, company volunteers have provided support to accomplished high school and university students with insufficient financial means since 1998. This year, scholarships were granted to 16 students. 120 students received tablet computers to facilitate their educational journeys.

Gender Equality Workshop for Children

During the year, Borçelik organized an educational workshop in collaboration with Istanbul Bilgi University's Child Studies Unit to raise the awareness on gender equality and enhance their critical thinking skills.

One Coil One Sapling

As part of the One Coil One Sapling initiative, Borçelik grows saplings in its 2 thousand square meter greenhouse located at its production site for replanting in the natural environment and safeguarding the future. In 2020, Borçelik planted 3,605 saplings from its greenhouse.

Support and Assistance Provided during the Pandemic

In collaboration with BUSİAD, Borçelik donated an Oxivent Oxi 4 Plus Ventilation device for use by Emergency/Intensive Care services of Uludağ University's School of Medicine. Borçelik also delivered assistance packages to support 500 families in collaboration with the Gemlik Municipality and District Governorate in conjunction with Vefa Social Support Group. In addition, Borçelik distributed face masks to 10 thousand persons in response to the pandemic.

Borçelik's Sustainability Priorities

Guided by stakeholders, a comprehensive

initiative was carried out to set Borçelik's

Sustainability Strategy Roadmap for 2020-

2030. Under this effort, Borçelik identified

sustainability priority areas and developed

goals and action plans.

Borçelik’s priority areas over the next 10

years period as set out in the roadmap

include: Circular Economy and Business

Models, Climate Crisis, Safe Work,

Human and Society, Digitalization, R&D

and Innovation, and Integrated Risk

Management.

Moving Forward under the

TURQUALITY Program

Under the TURQUALITY program, Borçelik

bolstered the image of the Borçelik brand in

target markets and continued efforts geared

toward becoming a global player. To expand

into new target markets, brand registration

applications were filed for the Borçelik brand

in three countries in 2020. Currently, Borçelik

has seven TURQUALITY target markets.

Measures to Fight against the

COVID-19 pandemic

In response to the pandemic, Borçelik

formed a COVID Crisis Group made up of

department heads across the organization

to decide on anti-Covid-19 actions and

measures for common implementation. The

Group engaged in a wide range of activities.

As a result of the Group’s efforts, Borçelik

obtained a Safe Production Certificate

from TSE (Turkish Standards Institute). In

addition, the TÜV-SÜD Hygiene Audit was

successfully performed in collaboration with

MESS. The Bi’işler digital application helped Borçelik to perform contact tracing promptly and easily

identify possible COVID-19 cases. Further

spread of the coronavirus was minimized via

scanning the QR codes in company shuttles,

dining facilities, staff locker rooms, and pool

vehicles. New arrangements were made in all

common spaces to re-configure capacities;

efforts were undertaken to ensure social

distancing and adequate hygiene; internal

and external audits ensured continuous

monitoring of all anti-COVID measures.

During the pandemic period, additional

support was also provided to the workforce

via Borçelik’s nutritionist, psychologist, and

the Employee Support Line.

Continuous OHS

Borçelik’s occupational health and safety

policy aims to prevent unsafe working,

continuously improve hazardous situations,

and create a culture that gives feedback

on unsafe practices. Risk assessment,

site inspections, and behavior-based

safety management (Number Ten) tools

are regularly implemented at Borçelik.

Employees participate in each of these tools.

In 2020, Borçelik introduced a number of

new OHS practices. These included two

Behavior-Based Safety Management

(Number Ten) campaigns; Safe Line

Entrance and Traffic Safety; two specialized

OHS projects; Major Accident Prevention

audits; and Working at Height Control

systematics. During the year, Borçelik

delivered numerous training courses on

194 topics including Fundamentals of OHS,

Behavior-Based Safety Management

(Number Ten) Observer-Captain Training,

and On-the-Job Trainings. In 2020, Borçelik

delivered a total of 4,544 hours of OHS

training

Borçelik Technical Academy

Borçelik Technical Academy (BTA) was

initially established in 2014 to design

technical training for company employees

to develop/improve their competencies

and obtain corporate technical information.

Seeing professional training as a social

responsibility, BTA uses the funds raised

to improve professional training in Turkey.

Helping both aspiring youth and experienced

professionals to develop themselves,

BTA capitalizes on its technical training

experience across all sectors where it

has played an active role. BTA’s mission

is to serve as a training and certification

institution that contributes to developing a

well-qualified labor force. BTA is committed

to conducting all its activities in a reliable,

quality-focused, ethical and lawful manner.

In 2020, Borçelik Technical Academy (BTA)

engaged in the following activities:

• Online and face-to-face training in 166

sessions covering 8 thousand hours were

delivered by Borçelik Technical Academy

as a part of life-long learning activities for

Borçelik employees.

• BTA served as a successful technical

training solution partner of other

companies, delivering 160 hours of

professional training to persons outside of

Borçelik.

• BTA designed and deployed the

competency model system for internal

trainers under an effort to improve the

skills of trainers.

• BTA delivered 84 hours of training to

21 employees with its Crane Simulator.

Borçelik Technical Academy was

accredited in four industries and 17

international vocational qualifications and

35 sub-units by the Turkish Accreditation

Board (TÜRKAK) under code AB-0331-P

on May 12, 2020. On August 18, 2020,

BTA was authorized by the Vocational

Qualification Institution (MYK) under code

YB-249 and officially commenced testing

and certification activities for national

qualifications within its responsibilities.

• BTA delivered coaching to 90 students

from four vocational high schools under

the Student Development Program.

Looking toward the Future

In 2021, Borçelik plans to continue its

effective response to conditions arising from

the COVID-19 pandemic. Borçelik aims to

take major steps forward in Occupational

Safety, Digital Transformation, and New

Product and Service Development – its

strategic priority areas. Borçelik is committed

to maintaining its competitive edge as

Turkey’s largest galvanized steel producer

offering the highest quality. In the coming

year, Borçelik plans to introduce major

projects and efforts geared towards

bolstering its strong market position.

In 2020, Borçelik planted 3,605 saplings under the One Coil One Sapling initiative.

Support for students in needUnder the Borçelik Fund for Contribution to Education, company volunteers provide support to accomplished high school and university students with insufficient financial means.

In 2020, Borçelik filed three brand registration applications for three countries and currently has seven TURQUALITY target markets.

Borçelik Technical Academy provided 8 thousand hours of training in 166 sessions.

World's first virtual crane trainingBTA delivered 84 hours of training to 21 employees with its Crane Simulator

KEREM ÇAKIR

KEREM ÇAKIRGeneral Manager

Borçelik

COMPANY PROFILE

BorçelikProduct Portfolio

• Hot-dipped galvanized steel,

cold-rolled steel, and hot-rolled

steel (pickled and oiled), used as

industrial raw material.

• Production of various grades of

flat steel, including commercial,

drawing, extra deep drawing,

dual-phase, bake-hardening,

rephosphorized, high strength

low alloy (HSLA), high-carbon

and special alloy, enameling,

and structural steel.

Production Capacity

• Total production capacity of

1.5 million tons

• 600 thousand tons of cold-rolled

steel

• 900 thousand tons of hot-dip

galvanized steel

Metal Processing Capacity

(Kerim Çelik)

• Total metal processing capacity

of 500 thousand tons

• Bursa Steel Service Center:

340 thousand tons

• Manisa Steel Service Center:

130 thousand tons

• Adana Steel Service Center:

30 thousand tons

Sectors Served

• Borçelik serves the following

industries: household appliances,

automotive (OEM and Tier 1/2), panel radiators,

construction, color coating, pipe

and profile, packaging, metal

goods, and steel service centers.

• Kerim Çelik serves the following

industries: automotive sub industry, household appliances

(main and sub-sectors),

heating, cooling and ventilation,

electricity, electronics, lighting,

construction, elevator,

machinery, and spare parts

industries, radiator, silo and

poultry equipment, furniture, and

accessory manufacturers, cable

and conveying systems, pipe

and profile, steel service centers,

and other sectors.

Service and Manufacturing Center

• Gemlik

• Bursa Steel Service Center

• Manisa Steel Service Center

• Adana Steel Service Center

• Istanbul Sales Office

Partnership

• ArcelorMittal